Please enter a keyword to search

9.6.1 General

a. Means of escape

(1) Aboveground factory floors

One exit staircase is permitted to serve an aboveground factory floor provided:

(a) the habitable height of the floor shall not exceed 15m;

(b) the floor shall not be located above 4th storey; and

(c) the AFA of the floor shall not exceed 200m².

(2) Mezzanine floor

One open staircase is allowed to serve a mezzanine floor(s) within an aboveground factory floor provided:

(a) the aggregate AFA of the mezzanine floor(s) per factory unit shall not exceed 60m²;

(b) the open staircase has a width of at least 1m and be constructed of non-combustible materials;

(c) the maximum travel distance measured from remote point on the mezzanine floor(s) to the exits complies with Table 2.2A;

(d) the elements of structure of the mezzanine floor(s) are of at least 1-hr fire resistance rating construction;

(e) the habitable height of mezzanine floor shall not exceed 24m; and

(f) the mezzanine floor is only be used for store and/or ancillary office.

b. Structural fire precautions

Fire compartmentation between individual tenancy units within a terraced or flatted factory building shall be provided. The entire enclosure of each of these units shall be fire compartmented with walls and floors of at least 1-hr fire resistance rating.

c. Storage within PG VI premises

(1) In a non-sprinkler-protected factory with storage areas/ spaces:

(a) Where the aggregate storage areas/ spaces (including transient) within a factory unit exceeded 100m2, the entire factory unit shall comply with general warehouse requirements under PG VIII buildings, or

(b) Where the aggregate storage areas/ spaces (including transient) within a factory unit exceed 100m2, they shall be compartmented from the factory such that the areas/spaces of storage within the factory do not exceed 100m2.

(2) The area stipulated in Cl.9.6.1c.(1) can be increased to 700m2 if the factory is protected by an automatic sprinkler system.

9.6.2 Petroleum service stations

a. General

(1) Any site chosen shall be sufficiently spacious for it to be designed to minimise unauthorised access, i.e., it shall be away from areas of high human traffic and the entrances/exits of other buildings.

(2) The boundary line of petroleum service stations shall be at least 50m from any residential building, or 90m from any place of public assembly.

(3) The route for tank vehicles leading to petroleum service stations shall not pass through or be near to places of public assembly, as stated in Cl.9.6.2a.(2).

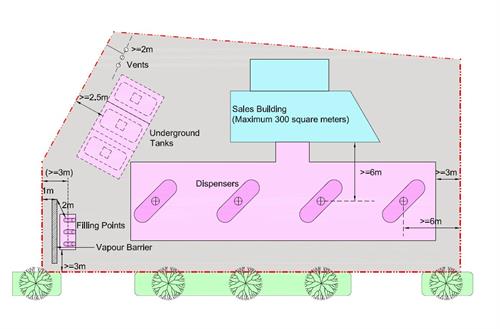

(4) A service station shall be stand-alone, and dispensing of petrol shall be restricted to the ground level only (see Diagram 9.6.2a.(4) ).

(5) Convenience stores integrated with the petroleum service station shall be at most 150m2.

b. Storage and tank requirements

(1) Tanks for all classes of petroleum in a petroleum service station shall be installed underground.

(2) All underground tanks shall have a water capacity of not more than 30kl each.

c. Tank requirements

The tank shall be designed, constructed, installed and tested to meet any of the following:

(1) BS 2594: Carbon Steel Welded Horizontal Cylindrical Storage Tanks, or

(2) Underwriters Laboratories (UL 58): Steel Underground Tanks for Flammable and Combustible Liquids, or

(3) Standards Association of Australia (1962): Steel Tanks for the Storage of Flammable and Combustible Liquids, or

(4) NFPA 30, Flammable and Combustible Liquids Code, or

(5) other equivalent standards.

d. Underground tanks and access pits

All underground tanks installations shall comply with the following requirements:

(1) the road surface above the underground tanks shall be of reinforced concrete of the thickness necessary to support itself and any superimposed loads, but not less than 150mm;

(2) the depth from the road surface to the top of the tank shall be not less than 450mm; and

(3) each access pit shall be fitted with a cover that is watertight or raised above the level of the surrounding ground to prevent the entry of surface water, and be strong enough to withstand any superimposed loads. The strength of such a cover shall not be inferior to those of 5mm low carbon steel.

e. Separation from property boundaries and building foundations

The distance of the underground tank to any property boundaries and foundations shall be not less than 2.5m and 1m respectively (see Diagram 9.6.2a.(4)).

f. Corrosion protection

Any underground tank and its associated piping shall be protected from corrosion by one or more of the following methods:

(1) protective coating or wrappings, or

(2) cathodic protection, or

(3) corrosion-resistant materials of construction.

g. Venting

Each tank shall incorporate a vent to atmosphere for the vapour space above the liquid to allow vapours to vent to the atmosphere.

h. Vent capacity

The size of any vent shall be such that pressure or vacuums resulting from filling, emptying or atmospheric temperature change, will not cause stresses in excess of the maximum design stress for the tank. The vent shall have a minimum internal diameter of 38mm.

i. Vent piping

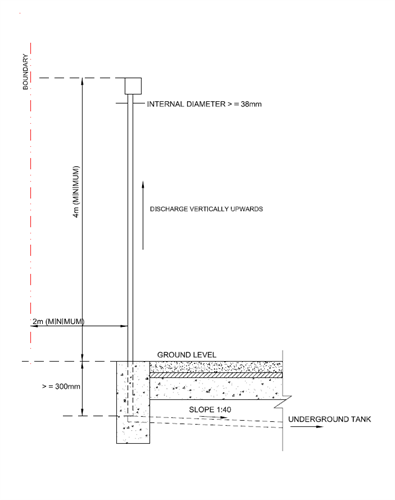

Any vent piping between the tank vent connection and the discharge point shall comply with the following requirements (see Diagram 9.6.2i):

(1) the vent pipes shall fall consistently back to the tank at a slope not less than 1 in 40;

(2) a vent pipe shall not pass through building foundations, but can be embedded in concrete, which is part of other types of building construction. A vent shall not be run within a cavity wall but can pass through a cavity wall or through masonry which incorporates cavities, provided that it is in a sleeve which will prevent vapour gaining access to the cavities; and

(3) a vent pipe can be either embedded in a concrete slab or laid in the earth. If the vent pipe is laid in the earth, it shall be:

(a) located not less than 300mm below ground level;

(b) surrounded by clean washed sand, or provided with equivalent corrosion protection;

(c) suitably protected if the area is subject to vehicular traffic;

(d) the vent pipe and its terminal shall be located or protected so that they are not liable to damage resulting from normal activities;

(e) the vent pipe shall be vapour-tight throughout its length; and

(f) all underground tanks or compartments in a tank shall have a separate individual vent pipe.

j. Vent outlet location

The discharge point of a vent shall comply with the following requirements:

(1) the location, direction and velocity of discharge shall be such that venting vapour will not cause danger to the surroundings;

(2) the vent discharge point shall be not less than 2m from any boundary or opening of a building, e.g. windows, doors, ventilators, air conditioners and forced air intakes (see Diagram 9.6.2a.(4)); and

(3) the vent shall discharge into open air and vent discharge point shall be located not less than 4m above ground level (see Diagram 9.6.2i).

k. Vent terminal

(1) The discharge end of a vent shall be protected from the ingress of foreign material by a protective cage of fitting and shall discharge only vertically upward in order to disperse vapours.

(2) A vent provision shall be connected to a vapour recovery or collection system, as similarly provided for at the filling mentioned in Cl.9.6.2l.

l. Filling connection

The filling connection to a storage tank, which is filled from a tank vehicle, shall incorporate a vapour-tight connection. A cap or cover with lock shall be provided for the filling point. A vapour recovery system shall be provided to prevent accumulation or abnormal discharge of vapour during refilling.

m. Location of filling point

The location of the filling point for any storage tank intended to be filled from a tank vehicle shall comply with the following requirements (see Diagram 9.6.2a.(4)):

(1) the length of any hose required to connect a tank vehicle to the filling point shall not exceed 5m;

(2) the filling point shall be protected from accidental or physical damage. Guardrails or any necessary measures shall be installed to prevent damage by collision;

(3) the filling point for any tank containing Class I, Class II or Class III petroleum shall be in open air at least 3m from any building opening or boundary. If a distance of 3m cannot be complied with, a vapour barrier made of material of at least 2-hr fire resistance rating shall be installed and shall not be less than 500mm above the centre of the filling point inlet. The vapour barrier shall be at least 1m from the boundary line. The distance measured in a horizontal plane around the end of any vapour barrier shall be 3m from the centre of the outermost filling point inlet to the building and boundary (See Diagram 9.6.2a.(4) for details);

(4) the edge of the tank vehicle designated parking area for refilling shall be at least 3m from any building opening or boundary; and

(5) the filling point for the underground tank shall be located in such a way that tank vehicles have unobstructed entry and egress from the service station.

n. Piping design suitability

The design, fabrication, assembly, test and inspection of piping shall be suitable for the expected working pressure temperatures and structural stresses and shall comply with relevant local (where available) or international standards.

o. Piping material suitability

Any material used in the construction or installation of piping shall be suitable for the conditions of use, and in particular:

(1) it shall be compatible with the particular petroleum or any other component with which it may be in contact;

(2) it shall be resistant to any heat (during operations) to which it may be exposed; and

(3) it shall be corrosion-resistant.

p. Piping flexible tube

Flexible tubing, piping or hose can be used only on condition that:

(1) the use of such tubing is unavoidable because of the need to provide for movement or to reduce the effect of vibration; and

(2) the tubing is of flexible metallic, metal-reinforced, armoured or other construction suitable for the working pressure, temperature and the liquid being handled.

q. Piping design and construction

The following general design considerations shall be taken into account when designing or installing any piping:

(1) the layout shall take into account the needs for all operating accesses and shall ensure that fire engine accessways are not impeded;

(2) supports and fitting of the pipework shall be secure and the piping shall be not unduly exposed to mechanical damage;

(3) wherever necessary, provision shall be made for the expansion or contraction of the piping and its contents;

(4) any buried piping shall be protected from superimposed loads, ground settlement, etc.;

(5) any necessary electrical bonding and earthing shall be provided; and

(6) piping shall be painted and/or marked in a manner sufficient to facilitate identification of its contents.

r. Pump drive

Any motor or engine that drives a pump for use with any classes of petroleum shall be of the type specifically approved for such use.

s. Fuel dispensing system

(1) Dispensing units at a service station shall be located in the open air where they will be adequately ventilated. These shall be located such that all parts of the vehicle being served will be on the premises of the service station, and shall be sited not less than 6m away from any building, public roadway or boundary (see Diagram 9.6.2a.(4)).

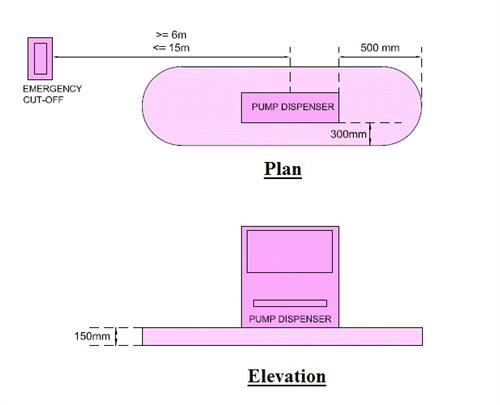

(2) A clearly identified and easily accessible switch or circuit breaker (a centralised Emergency Shut-Off Device) shall be provided at a location remote from the dispensing devices, including remote pumping systems, to shut off the power to all dispensing devices in the event of an emergency, and shall not be less than 6m or more than 15m from the dispenser. A sign incorporating the wordings “EMERGENCY CUT-OFF” shall be provided in the vicinity of the cut-off switch (see Diagram 9.6.2s.(2)). A similar device shall be provided in close vicinity to the console area/cashier as stipulated in Cl.9.6.2u.(1).

(3) Petroleum shall be transferred from underground tanks by means of fixed pumps designed and equipped to allow control of the flow and to prevent leakage or accidental discharge.

(4) A control shall be provided such that the pump will operate only when a dispensing nozzle is removed from its bracket or normal position with respect to the dispensing unit and the lever on this dispensing unit is manually activated. This control shall also stop the pump when all nozzles have been returned, either to their bracket or to the normal non-dispensing position.

(5) The dispensing unit and its piping shall be mounted on a concrete island. Each island shall rise not less than 150mm above the surrounding ground level and shall extend not less than 300mm on both sides of the dispensing units and at least 500mm from the dispensing unit to the edge of the base measured longitudinally (see Diagram 9.6.2s.(2)).

(6) The length of hose at each service station shall not exceed 5m. When not in use the hose shall be secured so as to protect it from damage.

(7) The nozzle through which fuel is dispensed to a vehicle shall be designed to automatically close when the fuel tanks of the vehicles are full.

(8) Individual dispensing units shall be provided with an emergency shut-off device.

(9) A rigidly anchored emergency shutoff valve, incorporating a fusible link or other thermally activated device, designed to close automatically in the event of a severe impact or fire exposure, shall be properly installed in the supply line at the base or inlet of each dispenser. The automatic closing feature of this valve shall be checked at the time of initial installation, and at least once a year thereafter by manually tripping the hold-open linkage.

t. Remote pumping systems

For systems where petroleum is transferred from storage to individual or multiple dispensing units by pumps located other than at the dispensing units, the following requirements shall apply:

(1) pumps shall be designed or equipped so that no part of the system will be subjected to pressure above its allowable working pressure;

(2) pumps installed above grade level shall be located not less than 3m from the boundary or building opening, and shall be substantially anchored and protected against physical damage; and

(3) pit lids or covers for subsurface pumps or piping manifolds of submersible pumps shall be in accordance with Cl.9.6.2d.(3).

u. Attended self-service stations

(1) The dispensing area at all times shall be in clear view of the console area/ cashier (area having control of the emergency shut-off devices for all and individual dispensing units, including remote pumping systems).

(2) The console/cashier operator shall at all times be able to communicate with persons at the dispensing area. This can be by means of a voice communication system.

(3) Sufficient close circuit cameras are to be installed at the petroleum service station to cover the forecourt, backcourt, dispensing areas and other critical areas of the petroleum service station.

(4) Provisions must be made for bollards and chains to be installed at the exit and the entrance of the petroleum service station during refilling by the tank vehicle to be utilised during high alert situations.

(5) The setback distance from the edge of the roof of the dispensing area to any boundary line must be in accordance to the requirements of Cl.3.5.3, or 3m, whichever greater. (See Diagram 9.6.2a.(4))

v. Electrical equipment and area classification

(1) General

All electrical wiring and equipment shall be of a type suitable for the location, in accordance with NFPA 70 or IEC 60079.

(2) Electric Vehicle (EV) Charging Station

(a) EV charging station located within a petrol station shall be in the following order of priority:

(i) Open-to-sky areas.

(ii) Forecourt.

(b) Main isolation shut-off switches shall be provided as follows:

(i) An emergency main isolation shut‑off switch for an EV charging station must be located so that a person does not have to travel more than 15m from the EV charging station and its associated parking lot to reach the switch.

(ii) If there is more than one EV charging station, one or more than one emergency main isolation shut‑off switch may be shared between EV charging stations within the same storey. The switch or switches must be located so that a person does not have to travel more than 15m from any EV charging station and its associated parking lot to reach the switch.

(iii) Every emergency main isolation shut‑off switch for an EV charging station must be located on the same storey as the EV charging station, so that there is a safe means of isolating the main electrical power supply to the entire electric vehicle charging system on the same storey upon activation of any one of those switches. Those switches must be capable of being activated manually without the use of a key or tool, or any special knowledge or effort.

(iv) Subject to Cl.9.6.2v.(2)(b)(v), the nearest edge of an emergency main isolation shut‑off switch must be located at least 3m away from an EV charging station and its associated parking lot.

(v) An emergency main isolation shut‑off switch may be located less than 3m away from an EV charging station and its associated parking lot, if there is at least another emergency main isolation shut‑off switch located at least 3m away but within 15m of that EV charging station and its associated parking lot.

(vi) An emergency main isolation shut‑off switch must be located between 800mm and 1.2m (inclusive of both measurements) above the finished floor level.

(vii) An emergency main isolation shut‑off switch must be in a clearly visible and easily accessible location, and be clearly labelled.

(viii) There must be clear instructions (however indicated) on how an emergency main isolation shut‑off switch may be operated.

(ix) There must be one or more than one signage, on which any letter must bear a height of at least 50mm and that is displayed in a prominent location from the emergency main isolation shut‑off switch, directing a person on how the switch is to be operated.

(x) Where an emergency main isolation shut‑off switch cannot be seen clearly from, or is not within the line of sight of, an EV charging station and its associated parking lot, any number of additional signages as may be necessary must be displayed for the purpose of directing persons to the emergency main isolation shut‑off switch.

(c) There shall be at least 12m separation distance between the EV charging station and the refilling points and vent pipes.

(d) There shall be at least 6m separation distance between the EV charging station and the designated oil tanker parking area.

(e) There shall be at least 8m distance separation distance from the EV charging station to any fuel dispensing unit.

(f) No electrical connection within EV charger shall be located within 500mm from the finished floor level of the forecourt.

(g) EV charging station shall be fully enclosed unless such openings are located at least 1m above the finished floor level of the forecourt.

(3) Battery Swap Station (BSS)

(a) BSS unit located within a petrol station shall be sited in the following order of priority:

(i) Open-to-sky areas.

(ii) Forecourt.

(b) Aggregate stored energy capacity of each BSS unit shall not exceed 20kWh. Where more than 1 BSS unit is installed, a minimum separation distance of 3m between BSS units shall be provided and the total aggregate stored energy capacity of all BSS units shall not exceed 40kWh.

(c) Separation distance

(i) BSS unit shall be placed at least 6m away from any exit access door.

(ii) BSS unit shall be located at least 1m away from parking lots (excluding the lots used for swapping of batteries).

(iii) Separation distance specified under Cl.9.6.2v.(2)(c) to (g) for EV charging stations shall be applicable to BSS units.

(d) Approved types of fire extinguishers of at least 2 numbers of 55A shall be provided.

(e) Emergency isolation switch shall be provided for each BSS unit.

w. Caution labelling

An emergency information panel shall be provided at the filling point.

x. Warning signs

(1) Warning signs shall be conspicuously displayed at the individual dispensing area incorporating the following wordings: “WARNING - NO SMOKING, NO NAKED LIGHTS, STOP ENGINE”. The lettering shall be at least 50mm high.

(2) The signs shall be displayed not less than 1.8m and not more than 2.5m above the ground level.

y. Firefighting and prevention

(1) Fire extinguishers

Approved types of fire extinguishers of rating not less than 70B (9kg) or 34B (2 x 4.5kg) shall be provided at the individual dispensing units and protected from the weather.

(2) Hose reels

(a) Sufficient hose reel coverage shall be provided such that the service station usable/accessible area is within 6m of a nozzle attached to a 30m hose.

(b) Hose reels shall comply with the requirements of SS 575.

(3) Absorbents

A small quantity of absorbent material or sand (as a guide, one full bucket minimum of 40 litres) shall be provided at the service station to mop up any spillage. These absorbent materials shall be kept in a container with a close fitting lid and shall be installed in an accessible place.

(4) Fire hydrant

Fire hydrants shall be within 50m from any part of the fire engine access road. The actual travel distance from the edge of the fire engine access road to the most remote point of the petroleum service station usable/ accessible space shall not be more than 50m.

9.6.3 High containment facilities

a. General

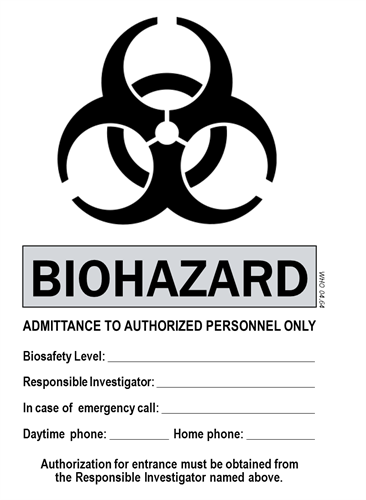

The purpose of this section of the Code is to stipulate fire safety requirements for high containment facilities and laboratories that handle biological agents or toxins, which are designed to meet the requirements of WHO and the authority having jurisdiction for Bio-Safety Level 3 (BSL-3) or higher.

b. General requirements

(1) A BSL-3 or BSL-4 containment laboratory shall be located at the ground floor and shall be separated from areas that are open to unrestricted traffic flow within the building. They shall be designed and constructed to comply with the requirements listed herein.

(2) The word “BSL-3” or “BSL-4” shall be stated clearly in the project title and printed on the top-right corner (lettering shall be bold, in red colour and at least 15mm in size) of all the fire safety plans of the high containment facility.

c. Fire compartment

(1) In a sprinkler-protected building, the high containment facility (including interstitial space, waste treatment areas, anterooms, etc.) shall be fire compartmented from adjoining spaces with at least 1-hr fire-rated walls, floor and ceiling. For a non-sprinkler-protected building, the fire rating shall be at least 2 hours.

(2) The protecting structure shall be constructed of masonry or drywall. If drywall construction is used, it shall be in accordance with Cl.3.8.7b.

d. Firefighter staging lobby

For high containment facilities, an additional (on top of the usual requirement to have a fire lift lobby next to exit staircases) firefighter staging lobby shall be provided to comply with the following requirements:

(1) it shall be located at every entrance of the facility;

(2) it shall be fire-compartmented with at least 1-hr fire resistance rating;

(3) in the absence of (1), an anteroom with the same fire resistance rating shall be provided to serve this function;

(4) it shall have at least 6m2 free working space;

(5) it shall comply fully with Cl.2.2.13b.(1) to (6), (7)(a) and (b); and

(6) it shall be installed with designated main landing valve, standby fire hose and fire hose reel.

e. Two-way emergency communication system

For a biomedical facility or building provided with a two-way emergency voice communication system, the two-way emergency communication system shall be extended to the firefighter staging lobby.

f. Fire detection and suppression systems

All high containment facilities shall be protected with sprinkler systems. High containment facilities without sprinkler protection shall comply with the following:

(1) smoke detectors shall be installed along the exterior of the periphery walls of the high containment facility;

(2) the fire protection circuit for BSL-3 or BSL-4 shall be grouped in a different fire zone for ease of identification;

(3) the fire protection systems shall be linked to the building fire alarm system and shall be connected to the SCDF Operations Centre through an approved alarm monitoring company; and

(4) if water discharge within the high containment facility is undesirable or unacceptable, the sprinkler system can be replaced by an approved fire extinguishing system.

g. Label and sign

(1) Caution labels shall be provided at all the laboratory entrances and exits in accordance with SS 586. In addition, a label indicating the information as shown in Diagram 9.6.3g.(1) shall be also provided.

(2) A sign shall be displayed at all entrances to the high containment facility, with the following wording: “In the event of fire or any water discharge, please notify the authority having jurisdiction for control of contaminated water runoff.”

Diagram 9.6.2a.(4) : Typical petroleum service station

Diagram 9.6.2a.(4) : Typical petroleum service station

Diagram 9.6.2i : Vent

Diagram 9.6.2i : Vent

Diagram 9.6.2s.(2) : Pump island

Diagram 9.6.2s.(2) : Pump island

Diagram 9.6.3g.(1) : Biohazard caution label

Diagram 9.6.3g.(1) : Biohazard caution label

9.6.4 Farm buildings

a. General

This set of fire safety requirements shall be applicable to farm buildings that meet the following criteria:

(1) the habitable height of the building shall not be more than 10m;

(2) the building shall be used for the sole purpose of farming (e.g. growing of crops, fish harvesting and egg production) and not involve activities such as packaging, storage and retail;

(3) other usages such as packaging, storage, retail, office and non-farming related production can be co-located within the building, provided they are compartmented and comply fully with the respective requirements stipulated in this Code; and

(4) the total computed Fire Load Energy Density (FLED) within the compartment that is used solely for farming shall not exceed 200 MJ/m2.

b. Fire Safety Requirements

(1) Occupant Load

The occupant load shall be based on the accessible floor area, excluding designated farming areas, on the basis of 30m2 per person.

(2) Width of corridor

Where the building is exempted from barrier-free accessibility compliance by the authority having jurisdiction, the clear width of corridor shall be at least 1m.

(3) Travel distance

The one-way and two-way travel distances shall not exceed 25m and 60m respectively.

(4) Fire engine accessibility

A fire engine accessway is not required, however a fire engine access road for access by firefighting appliances shall be provided to within a travel distance of 60m of every point on the project plan area of the building.

(5) Compartment size

The compartment size limitations given in Table 3.2A is not applicable. The maximum AFA per compartment shall not exceed 8000m2 and the maximum cubical extent per compartment shall not exceed 30000m3. The full height of the compartment shall be used for computing the cubical extent.

(6) Sprinkler system

An automatic sprinkler system shall be provided where the AFA of any compartment that is used for farming purpose, exceeds the compartment size limit stated under Cl.9.6.4b.(5).

(7) Smoke control system

An engineered smoke control system as specified in Cl.7.4.5 shall be provided where the AFA of any compartment that is used for farming purpose, exceeds size limit of 8000m2.

(8) Setback distance due to unprotected openings

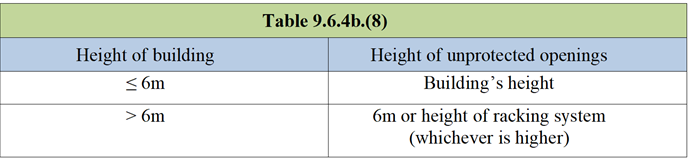

The requirements on setback of unprotected openings from building/notional boundary stipulated under Cl.3.5.3 shall be complied with and in accordance with Table 1 of Annex 3B. However, the height of the unprotected openings for greenhouses, used for the computation of the setback requirement, shall be in accordance with Table 9.6.4b.(8).

(9) Emergency voice communication system and Fire Command Centre (FCC) are exempted.

(10) External wall construction

The requirements of Cl.3.5.1a.(1) for non-combustibility of external walls need not apply for greenhouse buildings. Where plastic glazing materials are used as screens or shades for a greenhouse, the material shall comply with Table 3.15G.

9.6.5 Fuel dispensing system

a. General

This set of fire safety requirements shall be applicable to premises installed with fuel dispensing system other than petrol service station stipulated under Cl.9.6.2. Approval for the installation of fuel dispensing system shall be obtained from the relevant authority having jurisdiction.

b. Fuel storage tank

Fuel storage tank shall be installed in accordance with SS 532.

c. Fuel dispensing system

Fuel dispensing system shall be installed in accordance with Cl.9.6.2s..

9.6.6 Waste management and recycling premises involved in processing of flammable liquid waste

a. General

This set of fire safety requirements shall be applicable to waste management and recycling premises with any of the following processes:

(1) reconditioning of empty storage container that is used to store flammable liquid;

(2) disposal of flammable liquid waste; and

(3) recovery of flammable liquid waste.

b. General requirements

(1) Classification

(a) All recycling processes shall be classified under high hazard occupancy and shall only be located at grade level.

(b) For disposal and recovery processes stipulated under Cl.9.6.6a.(2) and (3), they shall comply with Cl.9.8.4.

(2) Spillage control

(a) Spillage control in accordance with SS 532 shall be provided to all areas where flammable liquid waste is located.

(b) For reconditioning process, each untreated container will shall be assumed to contain a remnant capacity of 10% volume of the container or the actual declared content, whichever is larger, to determine the spillage control stipulated in Cl.9.6.6b.(2)(a).

(3) Electrical wiring and equipment

All electrical wiring and equipment used within the processing areas shall be spark-proof and intrinsically safe in accordance with IEC 60079.

(4) Ventilation

Mechanical ventilation system in accordance with Cl.7.1.14 shall be provided for disposal and recovery processes.

(5) External processing area (open-to-sky)

(a) For external area, requirements stipulated in SS 532, e.g. separation distance, provision of fire engine access road, hydrant, etc., shall be complied with.

(b) Where separation distance is not able to comply with requirements stipulated in SS 532, use of 4-hr fire resistance rating masonry wall is allowed provided all of the following are complied with:

(i) The fire-rated wall shall be at least 1m above the stockpile and shall also intersect the direct line between the on-sites facilities and top of the stockpile. (see Diagram 9.6.6b.(5)(c)(i)).

(ii) The fire-rated wall shall be at least 2m beyond the outermost edge of the stockpile. (see Diagram 9.6.6b.(5)(c)(ii)).

(iii) When fire-rated wall is used, at least one façade shall remain open for firefighting accessibility.

Diagram 9.6.6b.5)(c)(i) - Use of fire-rated separating wall between processing area/storage to on-sites facilities

(b)(i).png?sfvrsn=7dadcd09_0)

Diagram 9.6.6b.5)(c)(ii) - Use of fire-rated separating wall between processing area/storage

(b)(ii).png?sfvrsn=eae60b57_0)

9.6.7 Electrical transformer room in underground structures

a. Scope

This set of fire safety requirements is applicable to electrical distribution transformer room located within underground structures e.g. consumer or power grid substation.

b. General requirements

(1) Compartment size and depth limits

(a) The AFA of each transformer room shall not exceed 250m2.

(b) The depth of the transformer room shall not exceed 9m below the average grade level and not more than one level below grade level.

(2) The transformer oil shall be tested to ASTM D 92 or ISO 2592 standard and with the fire point exceeding 300ºC.

(3) The underground structure housing the transformer shall not be sited within 15m travel distance measured between the nearest edges of the transformer door and exit staircase shaft.

(4) Provision to contain spillage of transformer insulating liquid shall be provided.

(5) Firefighting systems

(a) Automatic fire alarm system

(i) An automatic fire alarm system shall be provided for the electrical transformer room.

(ii) The fire alarm system for the underground transformer room shall be a dedicated zone, linked to the building fire alarm system. A summary fire alarm status (alarm/ fault) shall be provided to the main fire alarm panel in the building development.

(b) Fire suppression system

Automatic fire suppression system such as automatic sprinklers, foam-water sprinklers or water mist shall be provided for the electrical transformer room.

9.6.8 Sea-based buildings

a. General

This set of fire safety requirements shall be applicable to sea-based buildings that meet the following criteria:

(1) the building is more than one storey (including attic and mezzanine); or s

(2) any usage or part thereof used for Purpose Group V or VII.

b. Fire safety requirements

(1) Evacuee holding area

Evacuee holding area(s) on the basis of 0.3m2/person shall be provided. The designated evacuee holding area shall be open-to-sky and located not less than 3m from any unprotected openings. In lieu of the separation distance, a 1-hr fire-rated wall of at least 1.8m high shall be provided to separate between the unprotected openings and teh evacuee holding area. The evacuee holding area shall be located at first storey.

(2) Means of escape

One-way and two-way travel distance shall not exceed 15m or 30m, respectively as per Table 2.2A.

(a) Single storey structure

The travel distance shall be measured from the most remote point in any room or space to an open-to-sky space.

(b) Multi-storey structure

The travel distance shall be measured from the most remote point in any room or space to an exit staircase. An internal and/ or external exit staircase which serves as the required exit shall comply with the requirements stipulated in Cl.2.3.3;

(i) For mezzanine floors (excluding stay-in facility), one open staircase is permitted in accordance with Cl.9.6.1a.(2); and

(ii) Where there are stay-in facilities provided at the upper floor(s), at least two exit staircases shall be provided.

(3) Structural fire precaution

(a) Single storey structure

The element of structure (excluding the floor) shall be constructed of non-combustible material.

(b) Multi-storey structure

(i) The flooring immediately above the sea level need not be constructed of fire-rated or non-combustible material. For other parts of the building, element of structure shall be constructed of fire-rated and non-combustible materials, in accordance with Cl.3.3 and Table 3.3A, respectively.

(ii) Where wooden stilts are used for construction of sea-based building (e.g. Kelong), the part that is above the sea level shall be constructed of fire-rated and non-combustible material.

(4) Marine fire vessel accessibility

(a) To facilitate SCDF’s marine firefighting and rescue operations, there shall be unobstructed access to the evacuee holding area.

(b) A minimal 3m depth is required for berthing of SCDF’s marine firefighting vessels all-around the building.

(5) Fire protection systems

(a) Hydraulic hose reel(s) conforming to the requirements in SS 575 shall be provided to every storey of the building.

(b) Fire extinguishers complying with Cl.6.1 shall be provided to every storey of the building.

(c) Every part of the sea-based building shall be installed with a fire alarm system in accordance with Table 6.3A.

(6) Exit signs and emergency lightings

(a) Exit and exit directional signs shall be provided in accordance with Cl.8.1.7; and

(b) Emergency lightings shall be provided in accordance with Cl.8.1.3 and Cl.8.1.4, respectively.

(7) Solar Photo-Voltaic (PV) installation

Roof-mounted modules shall comply with Cl.10.2 in terms of:

(a) means of access;

(b) fire performance of PV modules;

(c) design and installation criteria; and

(d) emergency disconnection.

(8) Storage of flammable liquids

Storage of flammable liquids shall be located at the first storey. For the maximum capacity of flammable liquids, it shall be in accordance with SS 532 Table 1 - Minor Storage.

Updated 3 Mar 2025