Please enter a keyword to search

7.4.1 Provision

a. An engineered smoke control system as specified in Cl.7.4.5 shall be provided where:

(1) the requirements for compartmentation specified in Cl.3.2.1, Cl.3.2.4a. and Cl.3.2.4b. are relaxed under the conditions in Cl.3.2.6 for Atrium spaces in a building, or

(2) the total floor area of any compartment in a building or part of a building exceeds 5000m², or

(3) the total aggregate floor area of all basement storeys exceeds 2000m², except in any of the following situations:

(a) Where the basement or a portion of the basement is used as a car park, the car park shall comply with the requirements of smoke purging system in accordance with Cl.7.4.3, provided it is compartmented from the rest of the basement.

(b) Where a plant/ equipment room with floor area not exceeding 250m² is compartmented from rest of the basement, two doors remotely located from each other for better reach in firefighting operations shall be provided. The provision of a single door opening for this room is permitted provided the most remote part of the room is less than 8m from the door, and the equipment found inside this room, does not obstruct the throw of a water jet from a firefighting hose.

(c) Where a plant/ equipment room with floor area not exceeding 2000m², is provided with smoke vent in accordance with Cl.7.4.2 or smoke purging system in accordance with Cl.7.4.3.

(d) Where a compartmented service area comprising storerooms or workshops (restricted to staff only) is provided with smoke vent in accordance with Cl.7.4.2, or smoke purging system in accordance with Cl.7.4.3.

(e) Where the basement of a residential development is used as a car park, one office intended for ancillary use is permitted in the car park. The office shall be provided with smoke purging system in accordance with Cl.7.4.3 and compartmented from the rest of the basement. The office floor area shall not exceed 40m².

b. A smoke vent in accordance with Cl.7.4.2 shall be provided if the total aggregate floor area of all basement storeys does not exceed 2000m², except for PG I buildings . In lieu of smoke vents, a smoke purging system or an engineered smoke control system is permissible for car parks or other occupancies respectively.

7.4.2 Smoke vent

Smoke vents shall be adequately distributed along the perimeter of the space served, and its outlets shall be easily accessible during firefighting and rescue operations. Smoke vents shall comply with the following requirements:

a. the number and their sizes shall be such that the aggregate effective vent openings shall not be less than 2.5% of the floor area served;

b. the vent outlets, if covered under normal conditions, shall be openable in case of fire;

c. the position of all vent outlets and the areas they serve shall be suitably indicated adjacent to such outlets;

d. where ducts are required to connect the vent to outlets, the ducts shall either be enclosed in structure or be constructed to give at least 1-hr fire resistance rating; and

e. separate ducts and vent outlets shall be provided for each storey.

7.4.3 Smoke purging system

Smoke purging system, where permitted under this Code in buildings, shall conform to all of the following requirements:

a. The smoke purging system shall be independent of any other system serving other parts of the building.

b. The purging system’s purge rate shall be at least 9 air changes per hour.

c. The purging system shall be activated automatically by the building fire alarm system. In addition, a remote manual start-stop switch shall be located at the FCC, or at main fire alarm panel on first storey (where there is no FCC in the building). Visual indication of the operation status of the smoke purging system shall also be provided with this remote control.

d. Supply air shall be drawn directly from the external space and its intake shall not be less than 5m from any exhaust discharge openings. Outlets for the supply air shall be adequately distributed over the area served.

e. Where there is natural ventilation for the area served based upon evenly distributed openings equal to not less than 2.5% of the floor area of a given storey, such natural ventilation can be considered a satisfactory substitute for the supply part of the smoke purging system.

f. Replacement air shall be provided and if it is supplied by a separate mechanical system, such a system shall be connected to a secondary power supply.

g. Exhaust ducts shall be fabricated from heavy gauge steel of at least 1.2mm thickness.

h. The exhaust fan shall be capable of operating effectively at 250ºC for 2 hours and be connected to a secondary power supply.

7.4.4 Ductless jet fan system

a. General

This system can be used in lieu of a smoke purging system for conventional car parks where passenger cars/light weight vehicles are parked alongside each other with common driveways. It is not intended for mechanised car park systems or other forms of car parking systems.

b. Provision of sprinkler system

(1) The basement car park shall be sprinkler-protected in accordance with the SS CP 52.

(2) The arrangement of the sprinkler heads and the jet fans shall be such that, upon the operation of the jet fans, the effect on the spray pattern of the sprinklers is minimised.

c. Zoning of car park

(1) All car park spaces shall be divided into smoke control zones with each zone not larger than 2000m2 (excluding plant rooms and circulation spaces) for the purpose of smoke containment and quicker location of fire. A commissioning test will be carried out using hot smoke to demonstrate that smoke can be contained within each zone and channelled to the extract fans.

(2) Each smoke control zone shall have its own jet fan system (fresh air fans, exhaust air fans and jet fans) to purge smoke from the affected zone. The ducts shall be fabricated from heavy steel gauge steel of 1.2mm thickness. Alternatively, sharing of the fresh air and exhaust air fans is permitted provided the fans, wiring and control panel are protected with at least 1-hr fire resistance rating. The exhaust fan system shall also be designed to run in at least two parts, such that the total exhaust capacity does not fall below 100% of the required rate of extract for the zones affected in the event of failure of any one part. This requirement is also applicable for mechanised supply fan system, if it is used.

d. Jet fan system

(1) The jet fan system shall be activated by the sprinkler system serving the basement car park level and any other areas located within the same level. The activation of the jet fan system shall be confined to the smoke control zone on fire and all its adjacent zones. A firefighter cut-off and activation (override) switch shall be provided at the FCC. As an alternative form of fan activation, the use of smoke detectors to activate the jet fan system is allowed, provided:

(a) the detectors are positioned at the effective mid-range of the jet fan profile;

(b) in-duct smoke detector is located at the start point of the exhaust duct; and

(c) jet fan system shall only operate upon activation of two smoke detectors. This is to minimise false alarms.

(2) The jet fan system shall be provided with a secondary source of power supply through automatic operation of an emergency generator in case of failure of the primary power supply source.

(3) The jet fans shall be distributed at a spacing of 2⁄3 of the tested effective range of each jet fan. The tested effective range of the jet fan shall be taken as the distance up to the point at 0.2m/s of the air-velocity distribution profile.

(4) The minimum headroom for the installation of the jet fan system is 3m.

(5) The interaction of the various components of the jet fan system shall be as follows:

(a) Each group of exhaust fans for each smoke control zone shall be interlocked with its corresponding groups of jet fans for that zone.

(b) If the group of exhaust fans stops/ fails in any smoke control zone, the corresponding group of jet fans in that zone shall stop. But if any of the exhaust fans is still in operation in a particular smoke control zone, all the jet fans in that zone shall continue to operate.

(c) The exhaust fan shall continue to run even if any corresponding group of jet fans fails.

(d) The other groups of jet fans shall continue to run even if any one group of jet fans fails.

(e) If the fire alarm signal is isolated, the exhaust fans and jet fans shall continue to run at high speed. If the fans are manually restarted, both the exhaust fans and jet fans shall continue to run at high speed until they are set to low speed at the field control panel.

(6) The jet fan system shall be independent of any systems serving other parts of the building.

(7) The jet fan system design shall be such that the bulk air velocity induced by the jet fans is sufficient to stop the advance of the ceiling jet within 5m from the fire location in the direction opposite to the induced bulk air flow.

(8) The smoke control sub-panel in each smoke control zone is to be connected to the main smoke control panel, such that any isolation of jet fan system at a particular zone is automatically displayed at the main smoke control panel.

(9) The car park main smoke control panel at the FCC/ Guard house and remote local panel for the supply and exhaust fans shall indicate, by means of indicator lights, whether the fans are on low or high speed. The panels are also required to have the individual group of jet fans indication lights interlocked with the main exhaust fans in the respective smoke control zones.

(10) In the event of failure of the primary source of power supply and subsequent operation of the secondary power supply, the mode of operation of the jet fan system during the fire mode shall follow that prior to the failure of the primary power supply. For example, if the operation of jet fan system in a particular smoke control zone is switched off by the firefighter during fire mode condition and the primary source of power fails, the subsequent operation of the secondary power supply shall be such that the jet fan system remains in the previous fire mode condition, i.e., non-operational mode for that smoke control zone, while the other smoke control zones resume operation.

(11) The jet fan system design shall take into consideration the presence of any down-stand beams and other obstructions that are of depths of more than 1/10 of the car park floor to ceiling height so as to account for any resistance to airflow.

(12) On activation of the jet fan system, the movement of smoke towards the extraction point(s) shall not adversely affect the means of escape and cause smoke to be blown into the lobby area or exit staircases.

(13) The operation of the jet fan system should be such that there are no stagnant areas where smoke can accumulate in the event of fire.

(14) The operation of the jet fan system shall not cause the volume of air movement to be greater than that volume extracted by the main exhaust fans.

(15) There shall be at least one viable approach route (i.e. where acceptance criteria for firefighters are in accordance with Cl.7.4.4g. and Diagram 7.4.4e.(4)-2) for the firefighters to any possible fire location up to a distance of 5m from that fire. As such, information as to the viable approach route shall be displayed at the main fire alarm panel. This can be achieved by arranging the sprinkler control zone to correspond with that of the smoke control zone. Upon detection of the fire within a particular smoke control zone/ sprinkler zone, reference can be made to the display showing the viable approach route for that particular smoke control zone.

e. Wiring arrangement of jet fans

(1) All jet fans shall be connected to the local jet fan control panel in groups of not more than three jet fans.

(2) Each group will be connected by fire-rated cabling.

(3) Each group of jet fans will be protected by a separate MCB (main circuit breaker), with power supply compliant with SS 638, to prevent the failure of all the jet fans at once due to tripping of the main RCB, e.g., due to overloading.

(4) The jet fans shall also be wired in a zigzag configuration and no two consecutive jet fans in a straight line are to be wired in the same group. In the event of failure of one group of jet fans, the next corresponding group will be able to drive the smoke towards the exhaust location to be extracted (see Diagram 7.4.4e.(4) - 1 & 2). Should one group of jet fans fail, all other groups shall still continue to run.

(5) The location of the local control panel for the operation of the jet fans within each zone shall be in a relatively safe area within the zone and be spaced as least 5m apart from the local control panels of adjacent zones. This is to minimise the risk of a fire affecting all the control panels if they be spaced closely together, and thus rendering the ineffectiveness of the jet fan system.

f. Provision of supply air

(1) Supply air to the car park can be provided via mechanised supply air fans or by permanent openings of at least 2.5% of the floor area. Whichever is used, the maximum inlet air speed shall be 2m/s to prevent recirculation of smoke.

(2) The air velocity within escape routes and ramps shall not exceed 5m/s to prevent escapees from being hindered by the air flow.

(3) The replacement air intakes shall face away from any smoke exhaust points and be sited at least 5m apart so as to prevent recirculation of smoke. If the supply and exhaust louvers are located on the same façade of the building, they shall also be sited at least 5m apart.

(4) The replacement air intake shall be located on the opposing end of the smoke exhaust points so that there is no opposing flow between the supply air and the smoke that is drawn towards the exhaust fan.

g. Exhaust fan design

(1) The car park shall be provided with at least 12 air changes per hour during a fire. A lower air change not less than 9 air changes can be permitted provided the acceptance criteria stipulated in the Cl.7.4.4g.(1)(b) can be achieved through fire modelling:

(a) Hot smoke test/ CFD fire modelling

The effectiveness of the jet fans system design shall be demonstrated using hot smoke test in accordance with Cl.7.4.4j.. The heat release rate of the fuel load for the hot smoke test shall be at

least 1MW. The relevant PE or Fire Safety Engineer should decide on the fire location(s) that is (are) deemed most onerous with justification. In addition to the hot smoke test, Computational Fluid Dynamics (CFD) fire modelling will also be required

in the following instances:

(i) If air change per hour is smaller than 12.

(ii) If there are general goods vehicle or coaches where design fire size exceeds 4 MW (i.e., car fire).

(iii) If replacement air is a combination of natural and mechanical means.

(iv) If spacing of jet fans is more than 2/3 of the tested effective range.

The CFD study is to be endorsed by a Fire Safety Engineer (FSE) to verify the conformance of the jet fans system with the acceptance criteria

as stipulated in Cl.7.4.4g.(1)(b). The FSE is also required to put up a fire engineering report. Some of the accepted fire modelling software includes FDS, Swift-AVL, Fluent and Pheonics.

(b) Acceptance criteria

(i) Not more than 1000m2 of the car park space can be smoke-logged for at least 20 mins, regardless of whether the fire is located within the smoke control zone or across the zone boundaries (Note: After the 20 mins

duration, smoke is expected to remain confined within the 1000m2 area). Within this smoke-logged area, there shall be at least 1 viable route for the firefighters where the following conditions are satisfied:

* Smoke

temperature shall not exceed 250oC at a height of 1.7m from floor level.

* Visibility shall not be less than 5m at a height of 1.7m from floor level.

These conditions shall commence at a distance of 5m

from the fire location in the direction opposite to the induced bulk air flow induced by the jet fans. All other areas outside the smoke-logged area shall be kept substantially free from smoke i.e. smoke temperature not more than 60oC and visibility

of at least 25m (Diagrams 7.4.4e (4) - 1 & 2).

(Note: If hot smoke test is performed, assessment is to be made on the operation of the jet fans system, movement of smoke towards the extraction points and smoke spread.

The latter 2 aspects can be generally verified using the above visibility criterion. The temperature criterion need not be verified in view of the nature of the hot smoke test.)

(c) CFD fire modelling input parameters

(i) Fire Size

The design fire size shall be based on at least 4MW steady-state fire (i.e., car fire). For general goods vehicle, the design fire size shall be based on at least 10MW steady state fire (FSE is expected to provide justification

for the bigger fire size other than the car fire).

(ii) Type of fire

The type of fire shall be flaming polyurethane.

(iii) Location of fire

Generally, the fire should be located furthest away from the exhaust points and in between zones. The relevant PE or Fire Safety Engineer should decide on the

fire location(s) that is (are) deemed most onerous with justification.

(iv) Down-stand beams and other obstruction

The CFD model shall take into consideration the presence of any down-stand beams and other obstruction that are

of depths of more than 1/10 of the car park floor to ceiling height so as to account for any resistance to airflow and turbulence.

(v) Jet fan velocity profile

Validation model of the velocity profile is to be carried

out for a single jet fan. The data from the model shall be compared against physical test data.

As such, the jet fan shall be tested for velocity profile by an accredited testing laboratory for comparison with the simulated velocity

profile. The test report is to be attached to the Fire Engineering Report. The equation to be used for the deviation between the CFD profile and actual test profile is as follows:

Equation : Deviation = [(A-B) / B] X 100%

Where

:

A = distance/width/height from CFD profile

B = distance/width/height from actual test profile

The deviation of the distance, width and height of the actual profile from the simulated profile at the various air velocities

should be within 10%.

(vi) Duration of fire simulation

The duration of the fire simulation shall be at least 20 mins.

(vii) Sprinkler activation

The model shall assume there is no sprinkler activation for the design fire size specified in Cl.7.4.4g.(1)(c)(i).

(viii) Grid resolution

The grid size to be used in the fire model shall not be larger than 200mm X 200mm X 200mm in the smoke control zone where fire is located and its adjacent zones. Other than these zones, the grid size

shall not be larger than 400mm X 400mm X 400mm. Alternatively, the relevant PE or FSE undertakes a grid resolution study to ascertain the appropriate grid size needed for the fire size and smoke flows modelled (e.g., outcome of study showing that

additional resolution does not make much of a difference to the results).

(ix) Sensitivity study

A sensitivity study is to be carried out to show the impact of 1 group of jet fan failure nearest the fire on the overall

effectiveness of the jet fans system. This study is applicable to both fire modelling and hot smoke test. Notwithstanding the failure of 1 group of jet fans, the acceptance criteria must still be maintained.

(2) The capacity of the exhaust fan and any associated ducting shall be calculated on the basis that the pressure in the car park close to the extract points is equal to the external atmospheric pressure.

(3) Each smoke control zone of the car park shall have its own exhaust fan system. The exhaust fan system in each zone shall be designed to run in at least two parts, such that the total exhaust capacity does not fall below 50% of the required rate of extract in the event of failure of any one part, and that a fault or failure of the exhaust fan system in one zone will not affect the operation of the exhaust fan system in the other zones. The above requirement is also applicable for mechanised supply fan systems, where used.

(Note: If there is sharing of the exhaust air fans, see Cl.7.4.4c.(2))

(4) The smoke discharge points shall be located such that the smoke extracted from the smoke exhaust fans does not affect any occupied area or means of escape at the level where smoke is discharged.

h. Fire resistance of jet fan system

The jet fan system, such as the mechanised air supply fans, smoke exhaust fans, jet fans, duct works and wiring shall be capable of operating effectively at 250°C for 2 hours. The fans, ducts and wiring shall be tested in accordance with EN 12101-3, BS 476: Part 24 and SS 299, respectively.

i. Operations and maintenance manual

An operations and maintenance manual shall be attached. The manual shall contain the roles and responsibilities of the building owner/ operator, the restrictions placed on the building, identification of the sub-systems, servicing and maintenance plan, fault identification, etc. The manual can also be used as a guide for future renovations and changes to the building.

j. Commissioning test

The Registered Inspector who carries out commissioning test of the jet fans system may make reference to Table 2 of BS 7346 - Part 7 as a guide. When hot smoke test is performed, the PE/ FSE shall use a test fire size of 1MW. Reference may be made to AS 4391 on hot smoke test and PE is advised to make reference on how the test can be prepared and carried out in a proper manner.

7.4.5 Engineered smoke control system

a. Acceptable design guidance

The engineered smoke control system shall be in the form of a smoke ventilation system by natural or mechanical extraction designed in accordance with BR 186, BR 258, BR 368 and other acceptable standards:

b. Sprinkler system

A building provided with an engineered smoke control system shall be sprinkler-protected.

c. Fire size

(1) Non-industrial buildings

The capacity of the engineered smoke control system shall be calculated based on the incidence of a likely maximum fire size for a sprinkler controlled fire as recommended in the following table:

| TABLE 7.4.5c.(1) : FIRE SIZE FOR NON- INDUSTRIAL BUILDINGS | ||

| Occupancy (Sprinkler-protected) | Fire Size | |

| Heat Output (MW) | Perimeter of Fire (m) | |

| Shops | 5 | 12 |

| Shops (fast response sprinklers) | 2.5 | 9 |

| Offices | 1 | 14 |

| Hotel Guest Room | 0.5 | 6 |

| Hotel Public Areas | 2.5 | 12 |

| Assembly Occupancy with Fixed Seating | 2.5 | 12 |

(2) Industrial buildings

The requirements for design fire size are applicable to sprinkler- protected industrial premises (factory and warehouse) without in-rack sprinklers and limited to the design of smoke control system based on Cl.7.4.

(a) Fire growth

The fire growth can be evaluated by the following generic fire growth curve (also referred to as ‘t2 fire’), that represents the general types of combustible material present within an enclosure:

Qmax = ∝ (t-ti)2 ------------------------------------- equation (1)

where:

Qmax = heat release rate (kW);

∝ = fire growth parameter (kJ/s3);

t = time (s);

ti = time of ignition (s) (taken here as zero)

The fire growth parameter varies with the fire load density and the fire load configuration factor. However, for purpose of design, fire growth parameter can be generally defined as follows:

| TABLE 7.4.5c.(2)(A) : FIRE GROWTH PARAMETER FOR INDUSTRIAL BUILDINGS | ||

| Fire growth rate | Fire growth parameter (kJ/s3) | Time for Qg = 1MW (s) |

| Slow | 0.0029 | 600 |

| Medium | 0.012 | 300 |

| Fast | 0.047 | 150 |

| Ultra fast | 0.188 | 75 |

Note: The fire growth rate that is applicable through available literature or standard such as the SFPE Handbook shall be adopted. In the instance where the fire growth rate lies in between the range as stated above, the more conservative fire growth rate is to be used. | ||

(b) Design fire – sprinkler-protected

(i) The heat output of the design fire is assumed to increase according to equation (1) until sprinkler operation is deemed to occur at time t8. Following sprinkler operation, the heat output of the fire is considered to remain constant.

(ii) The capacity of the smoke control system shall be based on the fire size that is controlled by activation of 2nd ring of sprinklers.

(iii) The operation of the sprinkler system at ts and the corresponding fire size can be determined by hand calculations based on fire engineering principles or the use of fire engineering tools such as FPETool from National Institute of Standards and Technology (NIST). Whichever approach is used, the following design factors governing its calculation are as follows:

• Rate of fire growth

The type of fuel load and its configuration in the premises shall govern the rate of fire growth which can be represented using equation (1) and Table 7.4.5c.(2)(a).

• Sprinkler response time index (RTI)

The RTI is the thermal sensitivity of the sprinkler and shall be based on the manufacturer’s specification.

Example:

Standard response sprinkler – 105m0.5s0.5;

Fast response sprinkler - 50m 0.5s0.5;

ESFR - 26m0.5s0.5

• Temperature rating of sprinkler

The operating temperature of the sprinklers shall be based on SS CP 52 (e.g., 141°C or 68°C).

• Ambient temperature

Room temperature for air-conditioned spaces and non-air conditioned spaces can be taken as 25°C and 30°C, respectively.

• Ceiling height

The ceiling height shall be based on the height, measured from the finished floor level to the soffit of the ceiling/ roof.

• Spacing of sprinkler above fire

Sprinkler spacing shall be based on SS CP 52 (e.g. 3m by 3m or 4m x 3m).

Note: The application of FPETool from NIST or any other software in determining the activation time of the sprinkler system and the corresponding fire size has its limitations. Some of the software programs are based on Alpert’s correlations where a number of fundamental assumptions are made such as flat smooth ceilings, unconfined smoke flow, axisymmetric plumes (not near walls or corners), location of detector close to the ceiling, etc. Such assumptions shall thus be taken into consideration when using this tool.

(iv) The capacity of the smoke control system shall also take into consideration the possibility of forklift or general goods vehicle on fire along the internal ramps/driveways. For design purposes, the design fire size shall be taken as follows:

| TABLE 7.4.5c.(2)(b)(iv) : VEHICLE DESIGN FIRE SIZE | |

| Type of vehicle | Design fire size |

| Forklift or car | 4MW |

| General goods vehicle | 10MW |

(c) Determination of perimeter of fire

(i) Fire perimeter for forklift/car and goods vehicle

The fire perimeter is used to determine the mass flow rate of smoke. For forklift or general goods vehicle, the perimeter of fire shall be taken as follows:

| TABLE 7.4.5c.(2)(C)(I) : FIRE PERIMETER SIZE | |

| Type of vehicle | Perimeter of fire |

| Forklift or car | 5m x 2m |

| General goods vehicle | 9m x 2.5m |

(ii) Fire perimeter other than for forklift/car and general goods vehicle

Other than for forklift/car and general goods vehicle, the following equation is used to calculate the fire perimeter for a square fire of equal sides:

P = 4(Qc/Qr)0.5 -------------------------------- equation (2)

where:

P = fire perimeter (m);

Qc = convective heat output = 0.7Qmax (kW);

Qr = heat release rate per unit area (kW/m2), see Table 7.4.5c.(2)(c)(ii)

Where elongated storage configurations such as racking or shelving are used, the fire perimeter is determined using the following equation:

P = 2[Qc/(Qr x d)] --------------------------- equation (3)

where:

Qc = convective heat output = 0.7Qmax (kW);

Qr = heat release rate per unit area (kW/m2), see Table 7.4.5c.(2)(c)(ii)

d = depth of rack (m)

For purpose of calculating the fire perimeter, the values for Qr given in Table 7.4.5c.(2)(c)(ii) are used.

| TABLE 7.4.5c.(2)(C)(II) : HEAT RELEASE RATE | |

| Building Use | Heat release rate per unit area, Qr (kW/m2) |

| Industrial | 260 |

| Storage | 500 |

d. Capacity

The capacity of an engineered smoke control system shall be capable of handling the demand for smoke exhaust in a worst case scenario.

e. Clear layer

The design smoke layer base shall be above the heads of people escaping beneath it. The minimum height shall be 2.5m.

f. Smoke reservoir

(1) Smoke reservoirs to prevent the lateral spread of smoke, and to collect smoke for removal, shall be of non-combustible construction capable of withstanding smoke temperatures.

(2) For cases where smoke is removed from the room of origin, the smoke reservoir size for a smoke ventilation system shall not exceed:

(a) 2000m² for a natural smoke ventilation system; and

(b) 2600m² for a mechanical smoke ventilation system.

(3) For cases where smoke is removed from a circulation space or atrium space, the smoke reservoir size for a smoke ventilation system shall not exceed:

(a) 1000m² for a natural smoke ventilation system; and

(b) 1300m² for a mechanical smoke ventilation system.

(4) Reservoir length

The maximum length of the smoke reservoir shall not exceed 60m.

(5) Stagnant regions

Adequate arrangement(s) shall be made in each smoke reservoir for the removal of smoke in a way that will prevent the formation of stagnant regions.

(6) Perforated ceiling

For cases where the smoke reservoir is above the false ceiling, the ceiling shall be of perforated type with at least 25% opening.

g. Discharge of smoke

(1) Removal of smoke

For cases where smoke is removed from a circulation space or atrium space, the rooms discharging smoke into the circulation space/atrium spaces shall either:

(a) have a floor area of not exceeding 1000m² (for natural ventilation system) or 1300m² (for mechanical ventilation system), or

(b) be subdivided such that smoke is vented to the circulation space or atrium only from part of the room with floor area not exceeding 1000m² (for natural ventilation system) or 1300m² (for mechanical ventilation system), that is adjacent to the circulation space or atrium. However, the remainder of the room needs to be provided with an independent smoke ventilation system(s).

(2) Exhaust points

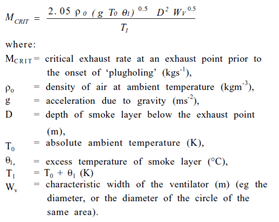

The minimum number and siting of exhaust points within a smoke reservoir shall be determined to prevent “plug-holing” effect at the exhaust points. The exhaust point shall comply with the following plugholing equation.

h. Limitations

Owing to practical limitations, a smoke ventilation system shall have:

(1) a maximum mass flow not exceeding 175kg/s; and

(2) a minimum smoke layer temperature of 18°C above ambient temperature.

i. Replacement air

(1) Replacement air shall by natural means be drawn directly from the external space.

(2) The design replacement air discharge velocity shall not exceed 5m/s to prevent the escapees being hindered by the air flow.

(3) Replacement air intake shall be sited at least 5m away from any exhaust air discharge.

(4) Replacement air shall be discharged at a low level, at least 1.5m beneath the designed smoke layer, to prevent fogging up of the lower clear zone.

(5) Where the inlet cannot be sited at least 1.5m below the smoke layer, a smoke curtain or a barrier shall be used to prevent replacement air disrupting the smoke layer.

(6) Where replacement air is taken through inlet air ventilators or door- ways, devices shall be incorporated to automatically open such inlet ventilators and doors to admit replacement air upon activation of the smoke ventilation system.

(7) Where the roller shutters are used as replacement air inlets in the design and installation of an engineered smoke control system or smoke purging system, they shall be of perforated type, having the required effective free area for the effective operation of the engineered smoke control system. Non-perforated type of roller shutters with solid surface shall not be used.

j. Emergency power supply

The engineered smoke ventilation system shall be provided with secondary source of power supply.

k. Mode of activation

(1) Automatic activation

(a) The engineered smoke ventilation system shall be activated by smoke detectors located in the smoke control zone. Use of smoke detectors for activation shall be carefully designed, so that accidental or premature activation of smoke detectors in a non- fire zone (due to smoke spills or spread from other areas) are avoided.

(b) Provision of activating smoke detectors shall comply with SS 645.

(2) Manual activation

A remote manual activation and control switches, as well as visual indication of the operation status of the smoke ventilation system, shall also be provided at the FCC. Where there is no FCC, it shall be indicated at the main fire alarm panel.

l. Interlocking with other ACMV systems

Except for ventilation systems in Cl.5.2.1g. and Cl.5.2.1h., all other air-conditioning and mechanical ventilation systems within the areas served shall be shut down automatically upon activation of the smoke ventilation system.

m. Standby fans/ multiple fans

(1) Either a standby fan or multiple fans with excess capacity shall be provided for each mechanical smoke ventilation system, such that in the event the duty fan or the largest capacity fan fails, the required smoke extraction rate will still be met. The standby fan shall be automatically activated in the event the duty fan fails.

(2) Fans shall be capable of operating at 250°C for 2 hours.

(3) Protected circuits

The fans and associated smoke control equipment shall be wired in protected circuits designed to ensure continued operation in the event of fire.

(4) Electrical supply

The electrical supply to the fans shall, in each case, be connected to a sub-main circuit exclusive thereto after the main isolator of the building. The cables shall be of at least 1-hr fire resistance rating in accordance with SS 299.

n. Smoke ventilation ducts

(1) Smoke ventilation ducts (both exhaust and replacement air ducts) shall be of at least 1-hr fire resistance rating. The rating shall apply to fire exposure from both the interior and exterior of the duct or structure and the duct shall also comply with Cl.7.1.2h..

(2) Where a duct passes through another fire compartment with higher fire rating, the duct shall be constructed to have fire-rating as that of the compartment. Where a duct is installed in a single fire compartment and does not pass through another compartment, smoke control ducts (both exhaust and replacement air ducts) within that compartment need not comply with the 1-hr fire resistance rating requirement subject to the following conditions:

(a) the smoke ventilation ducts (both exhaust and replacement air ducts) are constructed of at least 1.2mm thick galvanised steel sheet;

(b) sprinklers, designed to SS CP 52, shall be provided above and below the entire length of the ducts (regardless of the duct dimensions) to protect the duct surfaces from the effect of water spray through the activated sprinklers; and

(c) the construction and support of the duct shall conform to the appropriate requirements of the duct construction standards contained in ASHRAE Handbook, IHVE Guild books or SMACNA Manuals.

o. Fire damper

(1) Fire dampers shall not be fitted in the smoke ventilation system, except where used in an engineered smoke control system. In such a situation, the fire-smoke dampers shall be constructed in accordance with SS 333.

(2) The damper shall be in closed position during fail-safe mode.

(3) The combination fire and smoke damper, and any duct extension between it and the protected vent shaft, shall be of the same rating as the element of structure.

(4) Sprinkler protection shall be provided to the electric actuator.

(5) The electrical power supply cables to the electric actuator shall be fire resistant.

p. Time taken

The time for a smoke ventilation system within a smoke zone to be fully operational shall not exceed 60 secs from the time of activation.

q. Natural ventilation

Natural ventilation shall not be used together with mechanical ventilation.

r. Smoke curtain

All smoke curtains, where required, unless permanently fixed in-position, shall be brought into position automatically to provide adequate smoke-tightness and effective depth.

s. Obstruction to means of escape

A smoke curtain, or other smoke barrier, located at any access route forming part of or leading to a means of escape, shall not in its operational position obstruct said escape route.

t. Smoke or chanelling screens

Where glass walls or panels are being used as smoke screens to form a smoke reservoir or as channelling screens, they shall be able to withstand the design highest temperature.

u. Smoke control equipment

All smoke control equipment (including smoke curtains) shall be supplied and installed in accordance with BS EN 12101-1, BS EN 12101-3 and BS 7346 Part 7 or equivalent.

7.4.6 Fail-safe system

For natural smoke ventilation system, the natural ventilators shall be-

(1) in the “open” position in the event of power/system failure; and

(2) positioned such that they will not be adversely affected by positive wind pressure.

Note: Natural ventilators refer to any device e.g., entrance sliding doors or any other mechanised openings for fresh air replacement or smoke venting to external space.

Updated 3 Sep 2025