Clause 7.4 Redundancy for Mechanical Ventilation and Pressurisation Systems

7.4.1 Powered system

A standby fan (N+1) shall be provided for each of the following systems, such that in the event one of the duty fans fails or taken out of service, the standby fan shall be automatically activated to meet the required ventilation rate:

a. mechanical ventilation systems for:

(1) smoke-free/ fire lift lobbies;

(2) exit staircases; and

(3) essential rooms (e.g. sprinkler, hydrant, hose reel pump room, standby generator room, FCC, etc.).

b. engineered smoke control system;

c. smoke purging system; and

d. pressurisation systems for smoke-free/ fire lift lobbies and exit staircase.

---1.png?sfvrsn=30c93a8a_2)

Diagram 7.1.12c.(1) - 1: Unprotected opening perpendicular to the kitchen exhaust duct

---2.png?sfvrsn=1e8c6c8e_2)

Diagram 7.1.12c.(1) - 2: Unprotected opening parallel to the kitchen exhaust duct

.png?sfvrsn=2e781990_2)

Diagram 7.1.12c.(2): Fire resistance construction for kitchen exhaust duct

.png?sfvrsn=b51296b9_2)

Diagram 7.1.12c.(3): Installation of non-fire-rated kitchen exhaust duct above LPG cylinders

.png?sfvrsn=a39504b6_2)

Diagram 7.1.12c.(4): Installation of non-fire-rated kitchen exhaust duct in close proximity to LPG cylinders and vapouriser

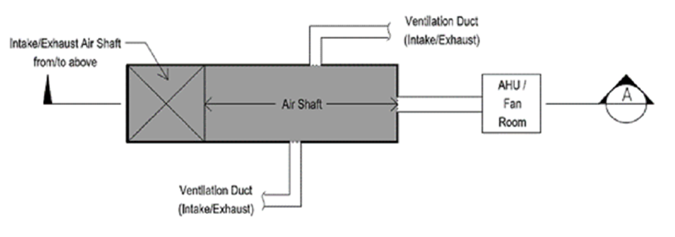

Diagram 7.1.16 - 1: Air Shaft Plan Layout

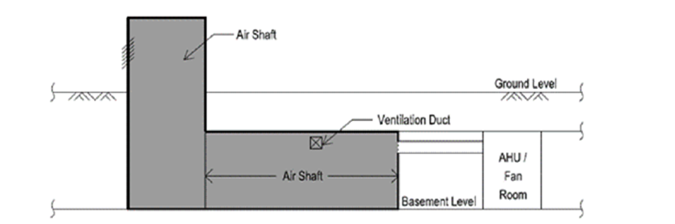

Diagram 7.1.16 - 2: Air Shaft Section A-A

| TABLE 7.1.16: TYPES OF PERMITTED SERVICES ROUTED IN AIR SHAFTS | |

|---|---|

| VENTILATION SUPPLY (VS) SHAFT | |

| 1 | Breeching inlet pipes for fire protection system. |

| 2 | Water metal pipes for domestic/ CD water supply, hydrant, and sprinkler. |

| 3 | Condenser water supply and return, condensate recovery metal pipes for aboveground cooling towers. |

| 4 | Water metal pipes for feed & expansion tank and cooling tower make up water tank. |

| VENTILATION EXHAUST (VE) SHAFT | |

| 1 | Sanitary waste and vent metal pipes (ejector and inspection chambers) |

| 2 | Pump drainage metal pipes |

| 3 | Fuel and vent pipes (in fire-rated enclosure) for day and bulk tank (for CD station only) |

| 4 | CD generator insulated exhaust metal pipes (for CD station only) |

| 5 | Low smoke zero halogen (LSOH) fire resistant or LSOH flame retardant earth cables for fuel inlet earth bar (for CD station only) |

| 6 | Non-flammable insulated refrigerant metal pipes and LSOH fire resistant or LSOH flame retardant cables for split air-conditioning units |

| 7 | LSOH fire resistant or LSOH flame retardant power & control cables for aboveground cooling towers |

| 8 | LSOH fire resistant or LSOH flame retardant power cables for mobile genset connection |

| 9 | Communication LSOH fire resistant cables running in metal conduits or trunkings for firefighter’s intercom. |

| 10 | LSOH fire resistant or LSOH flame retardant power cables for battery room |

| 11 | Insulated chilled water supply and return metal pipes |

) or https:// as an added precaution. Share sensitive

information only on official, secure websites.

) or https:// as an added precaution. Share sensitive

information only on official, secure websites.